Technique To Strengthen Ceramic

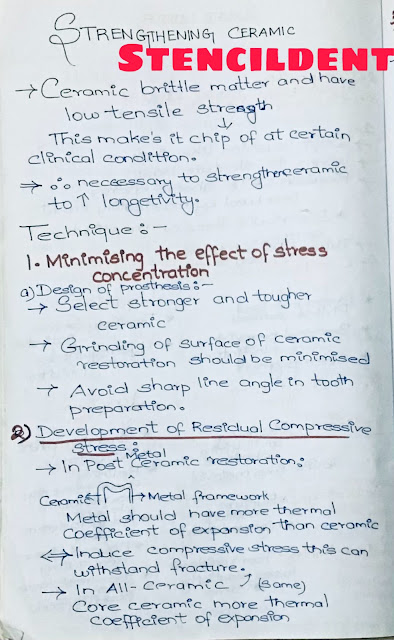

STRENGTHENING CERAMIC Ceramic brittle matter and have low tensile strength - this makes it chip of at certain clinical condition. Therefore necessary to strengthen ceramic to increase longevity. TECHNIQUE : 1)MINIMISING THE EFFECT OF STRESS CONCENTRATION: A)DESIGN OF PROSTHESIS: Select stronger and tougher ceramic Grinding of surface of ceramic restoration should be minimised Avoid sharp line angle in tooth preparation 2)DEVELOPMENT OF RESIDUAL COMPRESSIVE STRESS: In post metal ceramic restoration : Metal should have more thermal coefficient of expansion than ceramic Induce compressive stress this can withstand fracture In all -ceramic : core ceramic have more thermal coefficient of expansion 3)MINIMISING NUMBER OF FIRING CYCLES: Repeated firing will result in : weaker and fragile ceramic If we reduce the number the number of firing we can strengthen ceramic 4)THERMAL TEMPERING : Ceramic is heated to a higher temperature ,once...